HPX615E UTILITY VEHICLE

Work Series Utility Vehicle

- Electronic switch for instant 4WD engagement

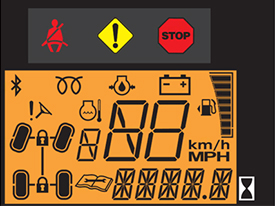

- New dash display, including fuel gauge

- 16.4 cu ft (.46 cu m) cargo box with a 1,000 lb (450 kg) capacity

- Real dumping cargo box with pickup-style tailgate

Apply For Financing

View Product Brochure

Features

Precision-engineered drivetrain system

Precision-engineered drivetrain system

The Gator™ HPX Utility Vehicle has a precision-engineered drivetrain system to better utilize engine power and to improve acceleration, hauling, towing, and hill-climbing capabilities. Power is transmitted from the engine through a continuously variable clutch system to the transaxle.

Key elements of the drive system include:

- Transaxle with high and low ranges, neutral, reverse, and park

- Engine

- Variable-speed drive

Variable-speed drive

Variable-speed drive

Variable-speed drive

The variable-speed drive consists of two clutches and a drive belt:

- Drive clutch is attached to and rotated by the engine.

- Driven clutch is attached to and drives the transaxle.

How variable-speed drive works:

- As the engine speed increases, the spring-loaded drive clutch is closed by weights being forced out by centrifugal force.

- As the drive clutch closes, the belt rides up to the largest diameter of the drive clutch and forces open the driven clutch.

- With the belt running in the smallest diameter of the driven clutch, the speed being transferred to the transaxle is increased.

- The driven clutch is designed to sense varying loads (inclines, mud, etc.) and constantly adjusts drive speed upward or downward so that engine rpm remains constant at constant throttle position.

- Start in gear, neutral, or park position for quick starting. The service brake must be engaged to start when in gear or neutral.

- To shift out of park, the service brake must be pressed to release the parking solenoid. An audible click will be heard and then the vehicle can shift out of park into the desired gear.

Shift lever

Shift lever

Transaxle and mechanical front-wheel drive (MFWD)

Transaxle and MFWD

Transaxle and MFWD

- Two-speed, fully enclosed, oil bath transaxle allows superior pulling ability

- Low range is 0 km/h to 19 km/h (0 mph to 12 mph)

- High range is 0 km/h to 40 km/h (0 mph to 25 mph)

- MFWD and rear transaxle are protected by skid plates

- Helical forward and reverse gears are used for quiet operation

- Selectable four-wheel drive (4WD) system with a limited slip front differential and dash-mounted electronic rocker switch

- Provides exceptional traction in challenging conditions

- More control descending hills with 4WD engaged – all four wheels help slow the vehicle down, and clutch engagement is still necessary to prevent free-coasting

- Near instantaneous torque to the front wheels once electronic switch is engaged

- Maintains turf-friendly operation in two-wheel drive (2WD mode)

- Combined with rear traction assist - (differential lock) can provide excellent traction in challenging conditions

Electronic rocker switch for 4WD and rear differential lock

Electronic rocker switch for 4WD and rear differential lock

Operator's station

Operator's station

Updated display

Updated display

Bench seat

Bench seat

Center console

Center console

The Gator™ HPX is equipped with many standard features that provide for comfortable and convenient operation:

- Bench seating provides room for one operator and one passenger

- Hip restraints serve as convenient and comfortable handholds

- Occupant protective structure (OPS) with three-point seat belts and passenger side grab handles, located on the front post, front dash, and on the outside of the seats

- Operator platform provides easy entry/exit for the operator and passenger

- Cup holders are located within reach of the operator's station

- Hour meter comes standard to assist in maintaining regular service intervals

- Traction assist (differential lock) is operated by electronic switch and conveniently located on the dash

- Glove box is located in the dash to provide a convenient storage area for small items

- Standard 12-VDC outlet conveniently located on the instrument panel

- Tank-mounted fuel gauge is easily viewed from the left side of operator's seat

- Large, 76-mm (3-in.) diameter fuel tank fill opening allows easy fuel fill and helps to eliminate spillage

- Storage compartment is located under the front hood for extra storage space

- On-dash manual choke provides easy accessibility and convenient choke moderation for smooth engine warm-up (gas models only)

- Display features include:

- Speed

- Fuel gauge

- Mechanical front wheel drive (MFWD)/rear diff-lock

- Gear position

Heavy-duty rear suspension

Heavy-duty rear suspension

The Gator™ HPX is equipped with heavy-duty, coil-over shock, semi-independent rear suspension with 89 mm (3.5 in.) of suspension travel. This provides a comfortable ride with the cargo box unloaded while also minimizing suspension sag when the cargo box is loaded.

Independent front suspension

Independent front suspension

The Gator HPX is equipped with a MacPherson strut, independent front suspension, providing a comfortable ride and excellent work capability. The heavy-duty, ductile cast-iron, single A-arm provides 131 mm (5.15 in.) of suspension travel for excellent handling and ride quality.

Standard OPS with nets

Standard OPS with nets

HPX815E with cab frame and nets

HPX815E with cab frame and nets

The Gator™ HPX is configured from the factory with OPS and standard occupant side retention (OSR) nets or deluxe cab frame.

- The OPS performance is certified to Society of Automotive Engineers (SAE) J219 standards.

- Glass doors can be dealer installed to complete the cab enclosure.

OSR

- Certified to American National Standards Institute (ANSI) B71.9 standards

Nets are standard equipment on the Gator HPX. Features of the nets include:

- One-handed operation

- Easy entry/exit

- Great visibility

Deluxe cargo box

Deluxe cargo box

Extra-durable deluxe cargo box ensures hard-working performance and longevity

The deluxe cargo box consists of a 15 percent glass-filled polypropylene composite material that eliminates rust and dents and reduces noise. The cargo box floor and front panel are made of steel.

Deluxe cargo box tailgate

Tailgate handle

Tailgate handle

Tailgate lowered to 150 degrees

Tailgate lowered to 150 degrees

The tailgate can be opened or removed to ease clean out and to carry longer items. The tailgate features truck-like performance and can be operated with one hand.

The standard-installed lanyards can also be removed to lower the tailgate 150 degrees for convenient loading and unloading tasks.

Deluxe cargo box tilt

Integrated handle for manual cargo box tilt

Integrated handle for manual cargo box tilt

The deluxe cargo box is easier to latch, unlatch, raise, and lower with the integrated handle design and gas assist. A prop rod is provided to hold the box in the upright position for operator convenience, as well as limit box pivot travel.

Integrated tie-down points

Integrated tie-down point in cargo-box bed

Integrated tie-down point in cargo-box bed

Additional tie-down points (TH shown)

Additional tie-down points (TH shown)

The deluxe cargo box offers integrated tie-down points for increased versatility. Tie-down points are located in the following areas:

- Four corners inside the cargo box bed

- Four points on the load guard directly behind the operator station (A)

- Tie-down bars on either side of the cargo box (B)

- Six points on the underside of the cargo box frame (circled)

Converting deluxe cargo box to a flat bed

Convert the cargo box to a flat bed (TX shown)

Convert the cargo box to a flat bed (TX shown)

Haul larger cargo on the flat bed (XUV825i shown)

Haul larger cargo on the flat bed (XUV825i shown)

The deluxe cargo box easily converts to a flatbed by removing ten bolts and unplugging rear lights (if equipped) at the harness pigtail at the rear of the machine. The flatbed configuration allows loading larger and irregularly shaped cargo.

Comfort and convenience packages

HPX vehicles are ordered with a comfort and convenience package, which includes factory-installed optional equipment.

Code |

Description |

HPX |

5101 |

Base comfort and convenience package -Deluxe cargo box with spray-in liner and brake and taillights -Cargo box manual lift |

Standard |

5105 |

Select comfort and convenience package -Deluxe cargo box with spray-in liner and brake and taillights -Cargo box power lift |

Upgrade option |

Optional accessories

Cargo box power lift (TX shown)

Cargo box power lift (TX shown)

Bed mat protects the steel floor from dents

Bed mat protects the steel floor from dents

Attachments for field conversion are also available to upgrade lighting and add equipment. Optional accessories for the deluxe cargo box include:

- Cargo box bed mat

- Cargo box power lift

- Side tool rack

- Cargo box divider

- 5-gal. (19-L) bucket holder

- Cargo box extender

- Cargo box side extensions

- Side- and top-opening toolboxes

- Taillight protectors

- Lighting kits

Cargo box specifications

| Length | 1143 mm (45 in.) |

| Width | 1320 mm (52 in.) |

| Depth | 304 mm (11 in.) |

| Volume | 0.46 m3 (16.4 cu ft) |

| Weight capacity | 454 kg (1000 lb) |

| Dump angle | 47 degrees |

CAUTION: Carrying extra-long cargo that extends beyond the box can adversely affect stability.

Gator™ Utility Vehicles

Gator™ Utility Vehicles

Overview

A JDLink™ M Modem connects a utility vehicle to the John Deere Operations Center, which enables you to manage your fleet of John Deere equipment more efficiently, increase productivity, and reduce labor costs. Whether you’re a farmer, professional landscaper, or municipality, with a modem and Operations Center, you are always connected to the work in progress and keep track of your utility vehicles, commercial mowers, tractors, and farm equipment.

JDLink M Modem

JDLink M Modem

JDLink M Modem

A JDLink M Modem is a factory-installed option for model year 2026 and newer one-row full-size XUV vehicles. A modem is included on vehicles ordered with GreenStar™ and AutoTrac™ ready option codes as well.

A modem can be field installed on the following vehicles:

- Model year 2018 and newer TS, TX, TX Turf, TH Gas, and TH Diesel

- GX Electric and GX Electric Crew

- Model year 2018 and newer HPX 615E and 815E

- Model year 2018 and newer XUV 560E, 560E S4, 590E, 590E S4, 590M, and 590M S4

- Model year 2018 and newer XUV 825E, 825M, 825M S4, 855E, 855M, and 855M S4

- XUV 835E, 835M, 835R, 865E, 865M, and 865R

- XUV 845M, 845R, 875M, and 875R

See compatibility section for serial number breaks and requirements.

John Deere Operations Center

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

John Deere Operations Center is available on PC, Apple iOS, and Android mobile apps

The John Deere Operations Center tracks your fleet and provides tools to analyze equipment data. The connected features vary by vehicle model.

Models |

Location and status |

Speed |

Geofencing and curfews |

Engine hours |

Odometer |

Maintenance planner |

Machine Analyzer Tool |

Fuel level |

Fuel consumption |

Diagnostic trouble codes |

Service Advisor Remote |

TS, TX, TX Turf, TH |

X |

GPS |

X |

Key |

--- |

X |

X |

--- |

--- |

--- |

--- |

GX Electric and GX Electric Crew |

X |

GPS |

X |

Key |

--- |

X |

X |

--- |

--- |

--- |

--- |

Model year 2018 to 2020 HPX 615E and 815E |

X |

GPS |

X |

Key |

--- |

X |

X |

--- |

--- |

X |

--- |

Model year 2021 and newer HPX 615E and 815E |

X |

GPS |

X |

Sync |

--- |

X |

X |

--- |

--- |

X |

--- |

XUV 560E, 560E S4, 590E, 590E S4, 590M and 590M S4 |

X |

GPS |

X |

Key |

--- |

X |

X |

--- |

--- |

--- |

--- |

Model year 2018 to 2020 XUV 825E, 825M, 825M S4, 855E, 855M, and 855M S4 |

X |

Sync |

X |

Sync |

X |

X |

X |

--- |

--- |

X |

--- |

Model year 2021 and newer XUV 825M S4 |

X |

Sync |

X |

Sync |

X |

X |

X |

X |

--- |

X |

--- |

Model year 2021 and newer XUV 855M S4 |

X |

Sync |

X |

Sync |

X |

X |

X |

--- |

--- |

X |

--- |

Model year 2018 to 2020 XUV 835E, 835M, 835R, 865E, 865M and 865R |

X |

Sync |

X |

Sync |

X |

X |

X |

--- |

--- |

X |

--- |

Model year 2021 to 2024 XUV 835E, 835M, 835R, 865E, 865M and 865R |

X |

Sync |

X |

Sync |

X |

X |

X |

X |

--- |

X |

X |

XUV 845M, 845R, 875M and 875R |

X |

Sync |

X |

Sync |

X |

X |

X |

X |

--- |

X |

X |

Location and status

Operations Center map displaying past locations

Operations Center map displaying past locations

Mobile view of Operations Center map showing GPS speed

Mobile view of Operations Center map showing GPS speed

The JDLink M Modem regularly transmits the location and operational status of each vehicle in the fleet so you can monitor progress in Operations Center.

- Location history-Display of map with current and past locations of each vehicle.

- Speed-Maps each vehicle’s current speed, so you can target operator training.

- Hours of operation-Reports the time of day the vehicle has been operated.

- Geofencing-Alerts when a vehicle enters or exits a prescribed area, for example if the vehicle has been stolen or an operator entered a prohibited area.

- Curfews-Alerts if the vehicle is operating outside prescribed times.

Engine hours

The modem regularly transmits the vehicle’s engine hours to inform maintenance planning and balance use.

- Sync-The vehicle reports actual engine hours to the Operations Center.

- Key-Engine hours are estimated by monitoring the key switch. Engine hours can be corrected in Operations Center.

Maintenance planner

Operations Center Maintenance Planner

Operations Center Maintenance Planner

Factory or custom maintenance plans can be established in Operations Center. Maintenance alerts are sent when engine hours reach maintenance intervals.

Machine Analyzer Tool

Operations Center Machine Analyzer Tool

Operations Center Machine Analyzer Tool

On select products, the modem reports the hours the vehicle spent working and idling. The Operations Center’s Machine Analyzer tool reports usage data which allows you to analyze operator behavior, identify causes of low productivity, and initiate corrective actions.

Fuel level

On select products, the modem reports the fuel level. On these products, an analysis of fuel consumption is available in the Operations Center Machine Analyzer Tool. Measuring fuel consumption enables you to address causes of excessive fuel use.

Diagnostic trouble codes (DTCs)

On select products, the modem transmits the trouble codes generated by the vehicle’s control units to the Operations Center. Addressing DTCs can reduce downtime and repair costs. For example, a low-engine oil pressure DTC can indicate an engine is low on oil. Addressing the issue can prevent costly downtime and repairs.

To help address issues quickly, when a DTC is generated, the Operations Center can display a push notification on the mobile app and send an email. Operations Center can also be configured to limit notifications to stop-level severity DTCs.

Service Advisor Remote

On select products, John Deere dealers can perform remote diagnostics, software programming, and adjustments without the cost of a service call.

Compatibility

A JDLink Modem is included on:

- Model year 2023 to 2025 vehicles ordered with option code 183E JDLink Modem. Option code 183E was only available with, and required on, GreenStar ready and AutoTrac ready vehicles.

- Model year 2026 and newer vehicles ordered with option code 183N JDLink M Modem. Option code 183N can be ordered as a stand-alone option and is required on GreenStar ready and AutoTrac ready vehicles.

A JDLink M Modem can be field installed on the Gator Utility Vehicles listed below. Field installation attachments simplify modem installation, and include mounting hardware, harness, and instructions. Field installation requires a JDLink M Modem to be ordered separately. The field installation attachments include a wiring harness therefore the modem should be ordered with the less harness option code.

Gator Utility Vehicle model |

Compatible model years |

Installation attachment** |

TS, TX, TX Turf, TH Gas, and TH Diesel* |

Model year 2018 and newer |

BUC11868 |

| GX Electric and GX Electric Crew | Model year 2026 and newer |

BUC11929 |

HPX 615E and 815E |

Model year 2018 and newer |

BUC11870 |

XUV 560E, 560E S4, 590E, 590E S4, 590M, and 590M S4 |

Model year 2018 and newer |

BUC11868 |

XUV 825E, 825M, 825M S4, 855E, 855M, and 855M S4 |

Model year 2018 and newer |

BUC11870 |

XUV 835E, 835M, 835R, 865E, 865M, and 865R |

Model year 2018 to 2024 |

BUC11871 |

XUV 845M, 845R, 875M, and 875R* |

Model year 2025 |

BUC11871 |

XUV 845M, 845R, 875M, and 875R* |

Model year 2026 and newer |

BUC11872 |

*The TE Electric and XUV 845E models do not support installation of a JDLink Modem.

**Installation attachments are expected to be available by Fall 2025.

Ethernet cable and switch kits

On model year 2026 and newer XUV 845M, 845R, 875M, and 875R vehicles, the optional BUC11879 ethernet cable connects a JDLink M Modem to a Generation 4 or 5 display which enables the JDLink M Modem to transmit precision ag technology data to Operations Center.

- Only vehicles equipped with a BUC11814 display and receiver integration kit benefit from BUC11879 ethernet cable since factory-installed GreenStar and AutoTrac ready options include this functionality.

- Model year 2025 and older vehicles are not compatible with BUC11879 ethernet cable.

Model year 2026 vehicles with a generation 4 display (4240 or 4640) also require a BUC11874 ethernet switch to adapt the generation 4 display. This applies to vehicles with factory-installed GreenStar ready option, factory-installed AutoTrac ready option, and vehicles with a BUC11814 display and receiver integration kit.

The following chart shows the ethernet cable and switch kits needed to connect a display to a JDLink modem to transmit precision ag technology data to Operations Center:

| Display | Configuration | Model year 2018-2022 XUV 835E, 835M, 835R, 865E, 865M and 865R |

Model year 2023-2024 XUV 835E, 835M, 835R, 865E, 865M and 865R |

Model year 2025 XUV 845M, 845R, 875M and 875R |

Model year 2026 XUV 845M, 845R, 875M and 875R |

| Generation 4 | Field-installed display and |

Unable to connect | Unable to connect | Unable to connect | BUC11879 cable BUC11874 switch |

| Factory-installed GreenStar ready | Never built** | Never built** | Included* | BUC11874 switch | |

| Factory-installed AutoTrac ready | Never built** | Included* | Included* | BUC11874 switch | |

| Generation 5 | Field-installed display and receiver integration kit |

Unable to connect | Unable to connect | Unable to connect | BUC11879 cable |

| Factory-installed GreenStar ready | Never built** | Never built** | Included* | Included* | |

| Factory-installed AutoTrac ready | Never built** | Included* | Included* | Included* |

* Nothing is needed because factory GreenStar and AutoTrac include connected modem.

**Factory-installed AutoTrac started with model year 2023 and factory-installed GreenStar ready started with model year 2025.

BUC11879 ethernet cable and BUC11874 ethernet switch are expected to be available by Fall 2025.

Specifications

| Key Specs | hpx615e-utility-vehicle Current Model |

|---|---|

| Engine power | 15.7* kW 20 hp |

| Cargo box dimensions | 1143 x 304.8 x 1320 mm 45 x 12 x 52 in. |

| Cargo box capacity (weight) | 454 kg 1000 lb |

| Towing capacity | 590 kg 1300 lb |

| Front suspension | Independent with McPherson Strut |

| Rear suspension | Coil over shock |

| Final drive | Two speed, oil bath |

| Four wheel drive | Yes |

| Fuel capacity | 20.1 L 5.3 U.S. gal. |

| Battery Options | |

| Cargo box volume | |

| Speed | |

| Engine | |

| Type | 2-cylinder, 4-cycle gas |

| Displacement | 617 cc |

| Power | 15.7* kW 20 hp |

| Cooling system | Liquid |

| Drivetrain | |

| Transmission | Continuously Variable Transmission (CVT) |

| Final drive | Two speed, oil bath |

| Four wheel drive | Yes |

| Traction assist | Positive locking, mechanically actuated (hand-operated) |

| Descent control | No |

| Ground speed | |

| Suspension | |

| Front | Independent with McPherson Strut |

| Rear | Coil over shock |

| Brakes | |

| Type | Hydraulic disc brakes |

| Park brake | Rear mechanical disk, hand operated |

| Tires / Wheels | |

| Front | 24 x 9.5-10 |

| Rear | 24 x 10.5-10 |

| Dimensions / Capacities | |

| Wheelbase | 1910 mm 75.2 in. |

| Weight | 681 kg 1500 lb |

| Length | 3022 mm 119 in. |

| Width | 1486 mm 58.5 in. |

| Height | 1867 mm 73.5 in. |

| Tread centers | Front: 1257.3 mm 49.5 in. Rear: 1219.3 mm 48 in. |

| Ground clearance | 152.4 mm 6.0 in. |

| Fuel capacity | 20.1 L 5.3 U.S. gal. |

| Cargo box dimensions | 1143 x 304.8 x 1320 mm 45 x 12 x 52 in. |

| Cargo box capacity (weight) | 454 kg 1000 lb |

| Payload capacity | 635 kg 1400 lb |

| Towing capacity | 590 kg 1300 lb |

| Hitch | Standard receiver, 5.1 cm 2 in. |

| Cargo box volume | |

| Features | |

| Color | Green/yellow |

| Power steering | No |

| Battery / Alternator / Power port | 480 CCA 40 amp at 3200 rpm |

| Instrumentation | |

| Storage | Cup holders, glove box |

| Seating | Bucket seats (bench available) |